Manufacturer Instructions is Critical for Elevator Safety

Understanding the Importance of Manufacturer Guidelines in Elevator Maintenance

Elevators, escalators, and other elevating devices must be properly installed, maintained, and tested to ensure public safety. While building codes and regulations provide clear guidance on many aspects of maintenance and inspection, there are cases where manufacturer instructions play a crucial role in determining safety requirements.

This directive clarifies when and how manufacturer instructions must be followed, particularly when specific procedures are not outlined in the ASME A17.1-2016/CSA B44-16 Code. If you manage a building, work as an elevator contractor, or oversee maintenance operations, understanding these guidelines is essential for compliance and safety.

Why Manufacturer Instructions Matter

Not all safety and maintenance requirements are explicitly covered in the elevator safety code. In some cases, the manufacturer’s instructions serve as the primary guide for maintaining, inspecting, and testing equipment. This applies to various elevator components, including backup systems and safety features.

If an elevator device is not specifically covered under Section 8.10 (Inspection and Testing) or Section 8.6 (Maintenance) of the Code, the manufacturer’s instructions must be followed. This ensures that all components are properly maintained, regardless of whether the safety risk is immediate or long-term.

Ignoring these instructions could lead to:

- Equipment failure due to improper maintenance

- Increased fire or operational risks

- Non-compliance with safety regulations

- Legal liability in the event of an accident

How Manufacturer Instructions Affect Maintenance and Testing

Devices Not Covered in the Code Must Follow Manufacturer Guidelines

Certain devices do not have specific inspection and maintenance requirements listed in the Code. In these cases, the manufacturer’s instructions must be followed to ensure compliance. This includes safety-critical backup systems, where redundancy does not eliminate the need for regular testing.

If a manufacturer provides product-specific procedures for maintenance, repair, inspection, or replacement, those instructions must be treated as mandatory. Failure to adhere to them could result in safety violations.

Tags, Plates, and Markings Must Be Followed as Specified

Elevators and escalators come with data tags, marking plates, and data plates that provide vital safety information. These markings include details about:

- Load capacity

- Inspection and maintenance requirements

- Safety testing records

The manufacturer’s instructions on these plates must be strictly followed unless otherwise stated in Sections 8.10 or 8.6of the Code. Any missing or damaged plates must be replaced immediately during routine maintenance to ensure compliance.

What Happens If Manufacturer Instructions Contradict the Code?

If there is ever a conflict between the manufacturer’s instructions and the ASME A17.1-2016/CSA B44-16 Code, the Code takes precedence. This means that if a manufacturer’s recommendations contradict safety regulations, the equipment cannot be installed or used unless it meets the Code’s requirements.

Alterations and Documentation Requirements

Alterations Must Include a Code Data Plate

When an elevator is altered, a code data plate must be installed. This plate must:

- Indicate the code and edition in effect at the time of alteration

- List the applicable requirements from Section 8.7 of the Code

This ensures that all modifications remain compliant with current safety standards.

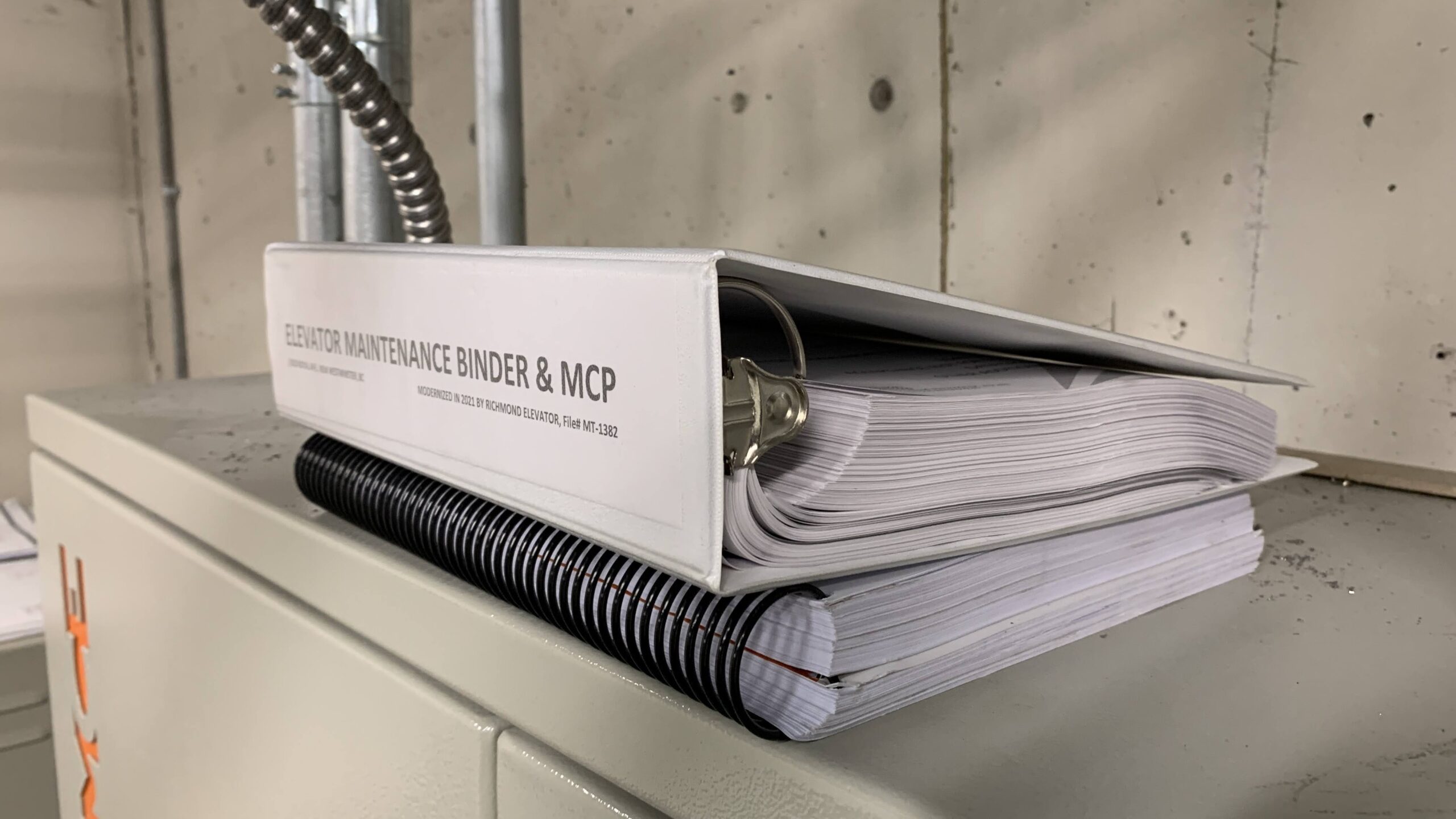

Required On-Site Documentation

Proper documentation must be maintained throughout the elevator’s lifespan. This includes:

- Unique procedures for maintenance, repair, and testing

- Manufacturer’s instructions for devices not covered in ASME A17.2

- Testing procedures and maintenance requirements

These documents must be stored on-site and kept fully intact for elevator inspectors and maintenance personnel.

Final Thoughts

Following manufacturer instructions is not just a recommendation—it is a requirement for safety and compliance. When the Code does not specify how to inspect, test, or maintain a device, the manufacturer’s guidelines become the standard.

By ensuring that all maintenance, inspections, and alterations follow the correct procedures, building owners and contractors can:

- Reduce the risk of elevator malfunctions

- Maintain legal compliance with safety regulations

- Ensure passenger safety and reliability

For full compliance, always check on-site documentation and verify that manufacturer instructions align with the latest ASME A17.1-2016/CSA B44-16 Code. If you are unsure about specific requirements, consult with a licensed elevator contractor or Technical Safety BC.